![]() Knowledge base

Knowledge base

- Coloring Techniques

- Decorating Techniques

- Transfer Print

- Direct Print

- Sublimation

- Magic Mug

- Galaxy Digital 360

- Sensitive Touch - sandblasting

- Laser Engraving

- Hand Made

- Additional decorations

- Delivery costs calculator

- Download

- FAQ

- CMYK imprint - worth to know before imprint

- Product certification

Anona, UAB

Anona, UABGedimino st. 47

LT44242 Kaunas

Tel.: +37037323765

E-mail: info@anona.lt

DIRECT PRINT

| DIRECT PRINT | ||

| Technology benefits | Technology limitations | Technological process phases |

| • low printing costs • dishwasher safe overprint (except for overprints on glass, metal and plastic) • perfect for motifs in solid colours |

• print in solid colours without bitmap elements • print on the external product's surface within outlined printing surface • printing up to 6 colours • it is not possible to apply a uniform embellishment of single colour over the whole standard surface of the print. • each time, in case of projects requiring to apply paint over the surface equal to (or greater than) 60% of the standard print surface for a given product, you need to consult your account manager. • minimal line thickness is 0,2 mm, in reverse - 0,4 mm • minimal size of writing is 7 pt., in reverse - 10 pt. |

• pattern's preparation for printing • print put directly on product • firing process |

___ Examples of Direct Print:

|

|

|

|

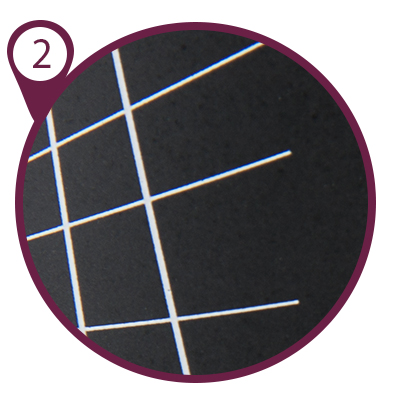

| Minimum negative line thickness: 0.4 mm |

Minimum positive line thickness: 0.2 mm |

a. Minimum negative font size: 10 points b. Minimum positive font size: 7 points |

Maximum number of colours: 6 24 – 107 pcs: print available only in a single colour from 108 pcs: print up to 6 colours |

Direct Print is available for the following products: